Newport Scientific, Inc.

"The Power of Superpressure and Precision"

Call us at 301-498-6700

Email us at sales@newport-scientific.com

"The Power of Superpressure and Precision"

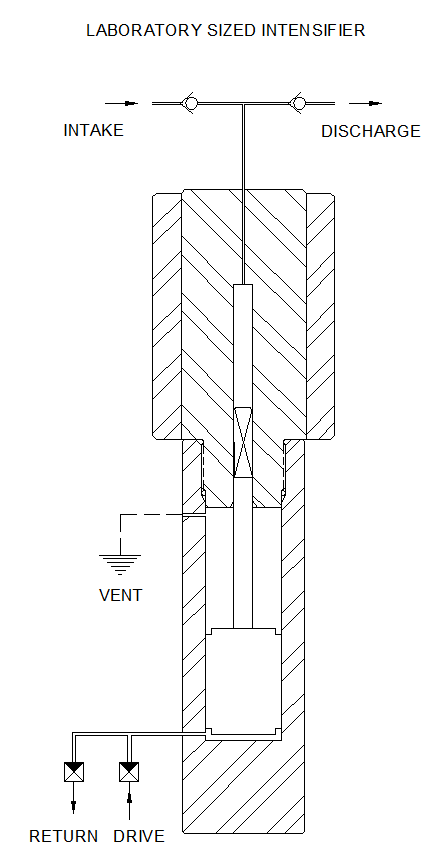

The Harwood Series 2.5 intensifier is a compact trouble-free, manually operated unit, of exceptional versatility and utility for operations on the laboratory scale. Designed for simplicity of operation and maintenance, the series 2.5 intensifier may be completely disassembled and reassembled in a few minutes. The high pressure cylinder is rugged monobloc construction of alloy steel.

Harwood intensifiers are characterized by relatively long strokes and large piston diameters. At least three advantages result: for a specified delivery volume this means fewer strokes and fewer applications of stress, hence less metal fatigue and longer life of all components. With fewer reversals of the pistons, the wear of moving seals is minimized. The longer the stroke, the less proportionately is the unswept volume – the volume between the end of the piston travel and the check valves outside the cylinder head – consequently the higher the efficiency.

The construction of the Harwood intensifier is such that there is no contamination between the high pressure and drive pressure fluids.

Series 2.5 intensifiers are single acting units, but can be used with auxiliary equipment as single piston pumps. These units are primarily useful in systems of small capacity where only a few strokes are needed to develop the pressure required.

The table below gives the general characteristics of Harwood Series 2.5 intensifiers. In general, an air operated pump is used to supply the drive and inlet pressures. For pressures above 140K a shrink fit mild steel jacket is supplied (as pictured). As an option, the intensifier can be fitted with proximity switches to provide a signal for automatic reverse at the end of each stroke. Other custom modifications are available upon request. Intensifier Chart, both single and double-acting, are also available.

|

Intensifier Characteristics |

|||||||

|

Model |

Maximum High Pressure PSI |

Minimum Inlet Pressure PSI |

Maximum Drive Pressure PSI |

Stroke |

Piston Diameter |

Displacements |

|

|

A2.5J |

200,000 |

5,000 |

13,750 |

4″ |

.625″ |

1.22 |

20.1 |

|

A2.5 |

140,000 |

5,000 |

10,000 |

4″ |

.625″ |

1.22 |

20.1 |

|

B2.5 |

100,000 |

5,000 |

10,000 |

4″ |

.750″ |

1.76 |

28.9 |